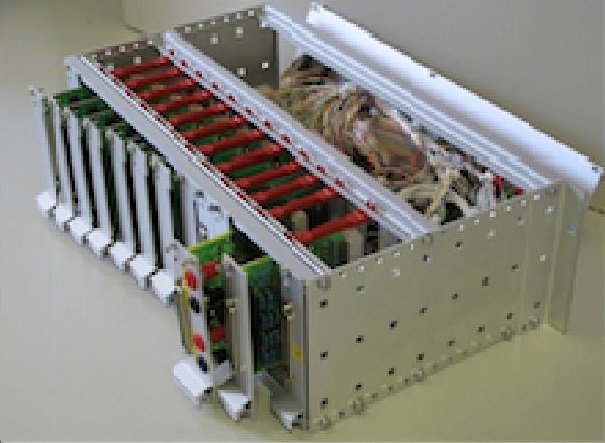

Test systems

We have produced several test systems equipped with software and automatic test procedures.

All the HW and SW laboratories collaborated in the development of the systems:

. System engineering (design analysis, functional high-level specifications)

. SW lab (SW Design and implementation, based on Customer frameworks)

. HW lab (Design, implementation and electrical and functional tests on various HW units)

. FPGA lab (Design, implementation and testing of FPGAs for functional test units)

. Physical design (Design of internal and external cables, design of 19'' metal boxes for HW development boards)

. Office design (Coding and verification of production documentation)

In addition, the following activities were carried out:

· TE internal wiring

· Acceptance and stand-alone verification of TEs

using self-check and self-test systems

· Certification CE